Bilge cleaning

Oceanic Green Group has a team specialised in carrying out bilge cleaning within a maximum of 72 hours, delivering services with excellence and issuing a report by robots, with photographs and videos of the rooms and the most difficult places to access.

We issue a report with photos and videos, validating the service all by robotics, certifying the service and 100% quality, for the captain and first mate, we provide a real-time inspection.

The product we use for the final wash of the service does not pollute the ocean or the cargo, guaranteeing our standard of sanitisation.

- 100% organic / ecological product,

- 100% natural organic disinfectant and descaling product registered with ANVISA and the FDA.

- Non-toxic, non-allergenic, no risk to human health

- Non-corrosive, non-alkaline

- Non-flammable

- 86% biodegradable,

- 100% ecological product, not harmful to the environment or aquatic fauna and flora.

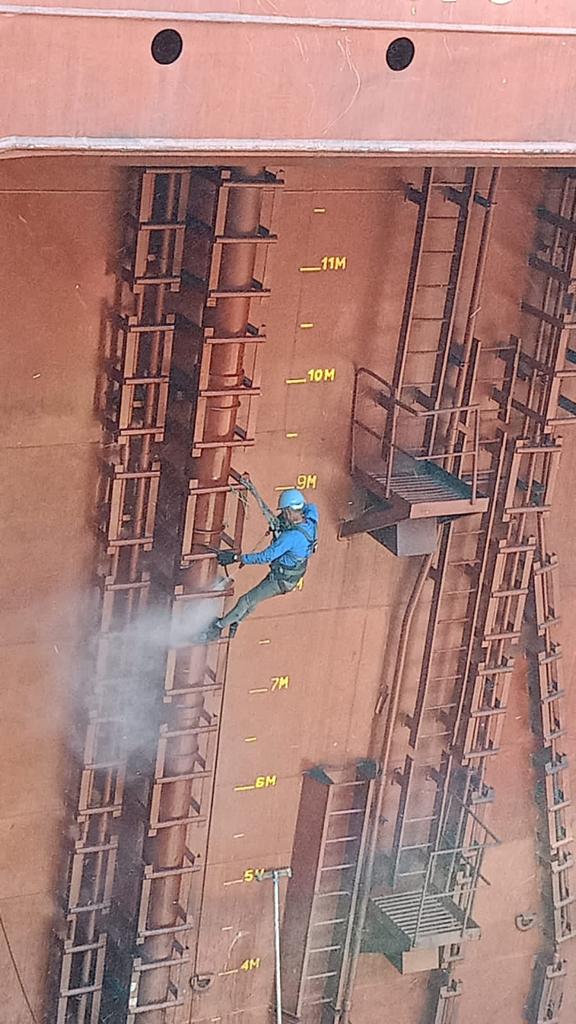

Preparing the hold is probably the most vital part of bulk carrier operations. If not carried out properly, it can result in substantial cargo claims, delays, additional cleaning, survey costs and costly off-hire disputes.

Potential reasons for failed retention inspections.

A vessel can fail a bilge cleaning inspection for a number of reasons which may include; excessive rust and flaking paint; previous cargo residues; odours and/or stains from paint or chemicals, infestation or damp.

Preparing the holds

- When preparing holds, the Captain should consider the following points, which are not exhaustive:

- Carefully review the voyage instructions and the Charter, consulting the vessel's Managers/Brokers.

The Captain should clarify whether there are any discrepancies in the cleaning requirements between the Charter and the Voyage Instructions.

Is there enough equipment on board?

Chemicals and applicators;

Hoses, hoovers, brooms, extension poles and scrapers;

Manure hoist and waste drums.

Most well-run bulk carriers today should have a Combi Gun or similar, which is capable of reaching the tops of the cargo compartments with sufficient pressure to remove residue and any rust and/or loose paint. Time needed between ports for bilge cleaning - weather conditions on the voyage, crew schedules or rest regulations.

Consideration of MARPOL regulations regarding washing water and cargo residues.It is essential to keep good records and photographic reports of bilge cleaning/maintenance operations. In the event of cargo claims, good records/records will help Owners demonstrate due diligence.